[Mac Safety] “Lathe vs. Milling vs. CNC: Everything You Need to Know”

Table of Contents

Modern manufacturing continues to evolve toward greater precision and productivity. From basic metal processing to advanced industries like aerospace, automotive, semiconductors, and medical devices, there’s a growing demand for parts that require high technical expertise. In such a competitive environment, the choice and operation of machining equipment are critical—not only to productivity but also to product quality, safety, and even a company’s long-term competitiveness.

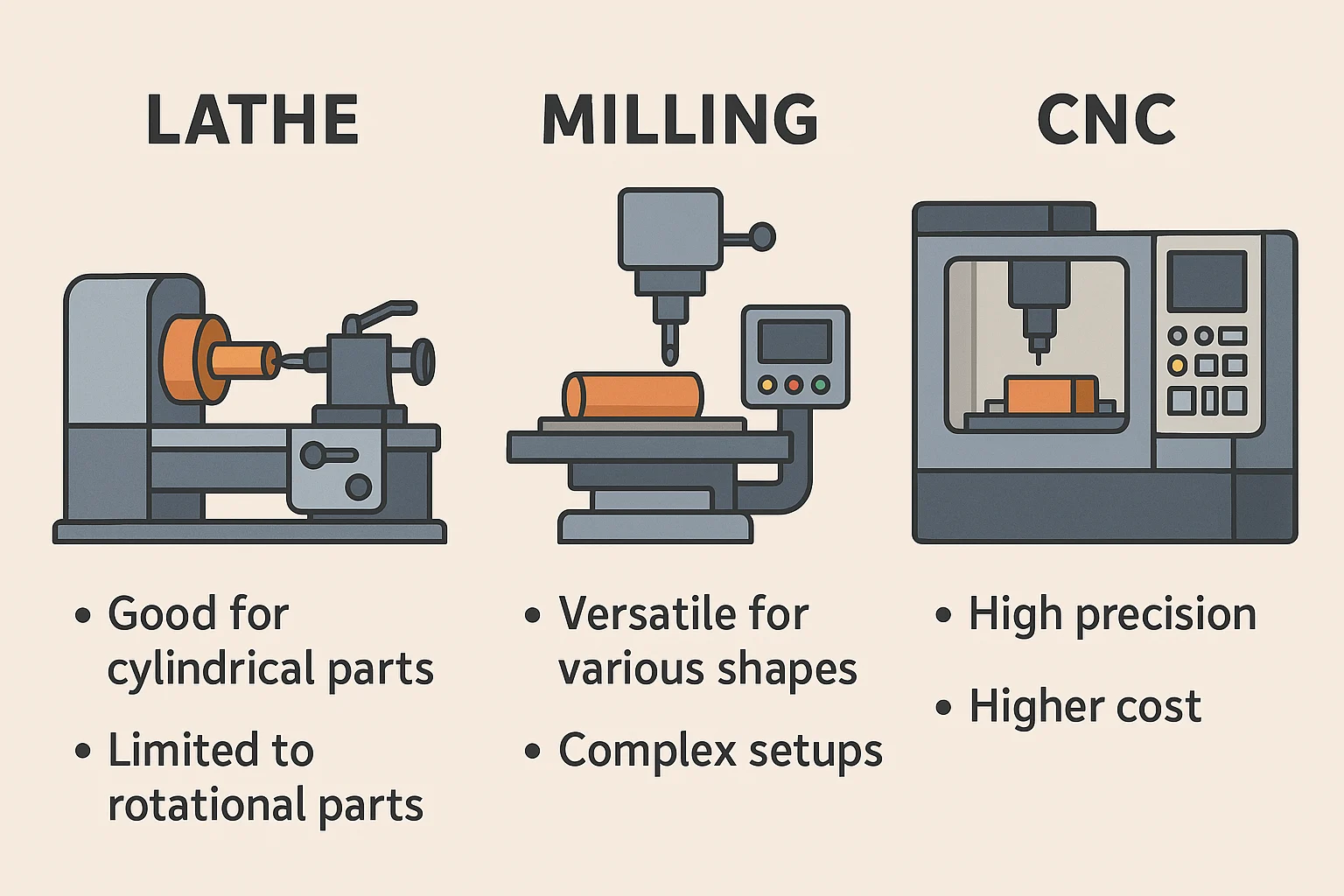

Among the most fundamental tools in machining are the lathe, milling machine, and CNC machine, each with unique roles and characteristics. Without a clear understanding of their differences, improper equipment selection or operation can lead to process inefficiencies, increased defect rates, and rising costs.

Additionally, understanding the operating principles and safety guidelines for each machine is essential for protecting the safety of operators on the shop floor.

This article aims to systematically present the concepts, advantages, disadvantages, real-world applications, and safety precautions of lathes, milling machines, and CNC equipment, so that readers can make smarter, safer decisions when working with or choosing these machines in their respective industries.

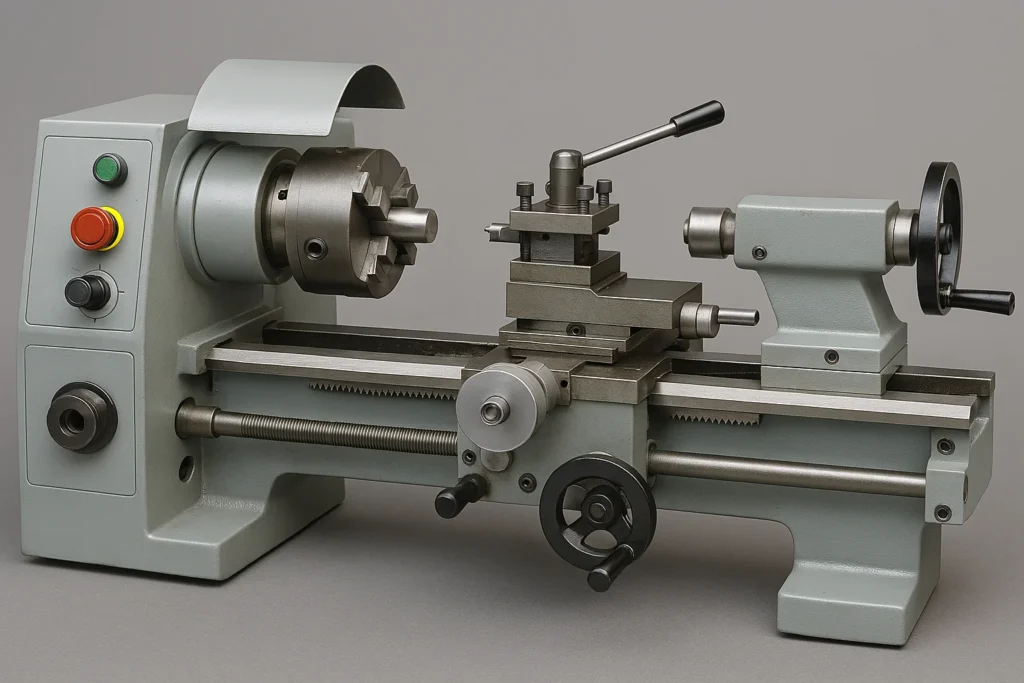

🔍 1. Lathe

📌 Definition & Principle

A lathe rotates the workpiece while keeping the cutting tool stationary (except for controlled movement across axes) to shape it as needed. The material is fixed to the spindle, which rotates it at high speed, while the tool moves horizontally or at an angle to cut the surface.

🛠 Key Components

- Chuck: Holds and rotates the workpiece

- Tool Post: Secures the cutting tool

- Carriage: Allows lateral movement of the cutting tool

✅ Advantages

- Ideal for cylindrical part machining

- Simple structure → low installation and maintenance costs

- Enables precise machining and supports various metal materials

❌ Disadvantages

- Cannot perform complex shapes like flat surfaces or contours

- Workpieces must be cylindrical

- Limited automation features

⚠️ Safety Considerations

- Watch out for hair, clothes, or gloves getting caught in rotating parts

- Sharp cutting chips → protective goggles required

- Loose material clamping can lead to ejection hazards

⚙️ 2. Milling Machine

📌 Definition & Principle

A milling machine keeps the workpiece stationary while the cutting tool rotates at high speed and moves to shape the material. Available in vertical, horizontal, and universal types.

🛠 Key Components

- Spindle: Rotates the cutting tool

- Worktable: Secures the workpiece and allows movement

- Feed Mechanism: Enables movement along X, Y, and Z axes

✅ Advantages

- Capable of machining flat surfaces, grooves, holes, and angled surfaces

- Suitable for molds, cases, and precision mechanical parts

- Can perform multi-task operations like drilling and boring

❌ Disadvantages

- Higher cost and maintenance compared to lathes

- Time-consuming setup

- Precision can vary depending on operator’s skill level

⚠️ Safety Considerations

- Keep hands and head away from fast-spinning tools

- Be cautious of flying chips and coolant splashes → wear goggles and protective clothing

- Always check if the workpiece is securely clamped during operation

🤖 3. CNC (Computer Numerical Control)

📌 Definition & Principle

A CNC machine combines traditional lathe or milling capabilities with computer-controlled automation. It interprets G-code and other numerical commands to control cutting tool paths without manual input.

🛠 Key Components

- CNC Controller: Interprets G-code and sends commands to the machine

- Servo Motors & Drives: Control movement of tools or worktables

- Additional Systems: Safety doors, warning lights, cooling systems

✅ Advantages

- High precision and repeatability → perfect for mass production

- Minimal human intervention → improves safety and productivity

- Multi-axis control (3, 4, 5 axes) → capable of handling complex 3D shapes

❌ Disadvantages

- High initial investment and need for skilled programming

- Maintenance and repairs are more complex and expensive

- Can be inefficient for small-batch or high-mix production

⚠️ Safety Considerations

- Never open the door during operation (interlock systems should engage)

- Programming errors can cause tool crashes or damage

- Sudden machine movements → run simulations before execution

📊 4. Extended Comparison Table

| Category | Lathe | Milling Machine | CNC Machine |

|---|---|---|---|

| Operating Principle | Workpiece rotates, tool is fixed | Workpiece is fixed, tool rotates | Automated cutting via computer control |

| Specialization | Cylindrical machining | Flat/shape-based machining | Complex shapes and high-precision work |

| Typical Use Cases | Shafts, rings | Molds, housings, flanges | Aerospace, molds, medical parts |

| Pros | Low-cost, simple, accurate | Versatile, detailed shaping | High precision, repeatability, automation |

| Cons | Limited to simple shapes | Setup time, expensive | Costly, requires skilled programming |

| Safety Concerns | Entanglement, flying chips | Flying debris, clamp failures | Unpredictable movement, door safety |

✅ Conclusion

Lathe, milling, and CNC machines form the three pillars of modern machining, each with distinct strengths and functions. From basic part shaping to ultra-precise industrial components, choosing the right machine for the task directly impacts both efficiency and quality.

Every machine also comes with specific safety protocols. Neglecting these can lead to serious operator injuries or equipment damage. By understanding and applying the appropriate usage techniques, you can ensure not just high-quality production, but also safe and efficient operations across the board.

![[OT Sec] The Imperative and Evolution of OT Security: The Impact of ICT Adoption and Key Examples](https://ota2z.com/wp-content/uploads/2025/01/DALL·E-2025-01-08-09.30.42-A-visually-detailed-representation-of-a-hybrid-Operational-Technology-OT-system-showing-interconnected-industrial-machines-control-panels-and-net-1-768x439.webp)

![[OT보안] 글로벌 OT 사이버보안 제도 패러다임 변화와 한국 지역특화산업 연계전략](https://ota2z.com/wp-content/uploads/2025/08/ChatGPT-Image-2025년-8월-1일-오후-03_13_51-768x768.webp)

![[OT Sec] The Importance of OT Security and Its Industrial Applications](https://ota2z.com/wp-content/uploads/2025/02/DALL·E_2025-02-03_10.21.22_-_A_modern_logistics_center_with_automated_convey-768x439.webp)

![[물리보안] PSP 자격증 완전정복: 물리적 보안 전문가를 위한 실무 가이드](https://ota2z.com/wp-content/uploads/2025/07/ChatGPT-Image-2025년-7월-27일-오후-10_13_59-768x768.webp)

![[OT Sec] The Last Defense for Production: Invest in OT Security Now, or It’s Too Late](https://ota2z.com/wp-content/uploads/2025/04/ChatGPT_Image_2025년_4월_26일_오전_10_32_09-768x512.webp)